I’m sure some of you might be rolling your eyes and thinking “I can’t believe she’s actually posting about something as simple as subcategories!” But strangely enough most Manufacturer content creators still don’t seem to realize how much their subcategory choices affect companies who would potentially accept or reject their content. So I am taking the time to help clarify why I think better practices will help Revit/ BIM Managers to integrate your families into their studio or global libraries.

WHAT CONTENT CREATORS SHOULD ALREADY KNOW

- Subcategories are used to control the visibility of specific geometry or linework in a view.

- They can also be used to define Object Styles within a project for standardized line settings, per family category and family subcategory. These settings are then enforced as the default and preferred graphical representation within the entire Revit project or template file.

- The Visibility Graphics Menu is completely dependent on the subcategories in a project and is used on a very regular basis on projects to control view settings where no View Template is being used.

- Many companies use View Templates in their projects which rely on a fixed list of subcategories.

- When new families are loaded into a project all NEW subcategories which were not originally in the project file prior to loading the family will automatically be set to be visible in all predefined project View Templates.

- As a result loading families with new subcategories will automatically disrupt all the existing View Templates in the hosting project file.

- By adding subcategories to projects that are ill-considered the project organization become inefficient. Revit modellers and drafters become increasingly irate with trying to hide, display or override objects using Visibility Graphics, Object Styles or View Templates.

- See below for a simple example of the impact that only 3 Manufacturers families can have to a project when loaded into a project.

BEFORE LOADING A SNIPPET OF A PREDEFINED VIEW TEMPLATE IN PROJECT

- This View Template example was designed to display fixed furniture only for plan views.

- All loose furniture had been set to be automatically hidden.

AFTER LOADING 3 FAMILIES FROM MANUFACTURERS INTO PROJECT

- Notice how cluttered the Visibility Graphics menu has become with all the additional subcategories.

- Note: These subcategory examples are from REAL Manufacturer’s content that I downloaded this evening. (The only thing that I have done to them is replace the Manufacturers name with a person’s name to avoid any public embarrassment for the Manufacturer or content creation company.)

- With so many new subcategories that are added just with 3 families it becomes easy to see why effective Revit system management requires that all Manufacturer’s content be cleaned up routinely.

- It is common practice to have to modify some subcategories in families but the goal should always be to minimize the amount of re-work that is imposed onto the end-user by creating and assigning subcategories appropriately in the first place.

SOME CONTENT CREATORS MAY SAY

“Michelle, It’s really not our problem. We can’t be expected to try to cater for all the Manufacturer’s clients and guess what everyone would name a subcategory! That’s simply ridiculous…”

And I’d reply “Your client, the Manufacturer, deserves the best uptake of their content range – so actually – it is your problem/ challenge. It’s reasonably easy to come up with a strategy for subcategories that would require at least the minimum amount of re-work for anyone who wishes to use your Revit families. Besides if your content proves to be popular and easy to integrate into company libraries then you will have a delighted client and a great reputation. So everyone wins.”

SUBCATEGORY NAMING GUIDELINES

Fortunately this is one example where there is already a baseline of subcategory examples that are commonly used by many content creation companies as well as some Design and Drafting firms. Yes, in this case I am promoting the ANZRS subcategory list, regardless of where in the world your content is being made. The list is generic and not region specific. It is comprehensive and at least a well-considered starting point for most content ranges. If a company has not adopted these subcategories they could still easily transfer these over to their company specific preference with minimal fuss. If you prefer to use your own naming conventions then that is perfectly fine provided that you don’t make the following mistakes.

CAN YOU SPOT THE ERRORS?

Let’s see if you can spot the issues below before I outline them and elaborate below the images.

WHAT DID YOU NOTICE?

IMAGE A

- Avoid assigning any geometry or line-work to the main family category.

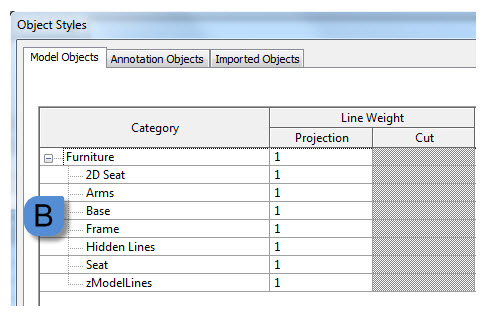

IMAGE B

- Too many subcategories have been used.

- Simple families might only need 1-2 subcategories.

- E.g.

- One for geometry

- One for linework or masking regions

- More complex compliance families may require a few additional subcategories.

- E.g.

- Clearance lines or for set-out lines

- This is only on rare occasions since Manufacture based content should be less specialized in terms of personalized graphic control settings. Erring on the side of less is always best.

- Use visibility parameters to control visibility if type based. E.g. With Arms or Without Arms but do not use subcategories to control this option.

- Only display what is essential in a plan or elevation view.

- Use a masking region and symbolic linework, if needed.

- Always think of what your families will display like at a scale of 1:100 keep your plan and sectional representations simple.

- Where possible use a simple subcategory descriptor that can apply to items of a similar grouping that you would expect drafting teams to want to control together.

- E.g. It is highly unlikely that drafters will want to display sofas and not chairs. In this case ‘Seating’ as an appropriate subcategory will suffice.

- In some cases it might make sense to make a distinction between loose and fixed items but this is solely driven by general industry documentation expectations.

IMAGE C

- It is essential to ensure that ANY geometry and symbolic line work be assigned to an appropriate subcategory.

- Edit the masking regions to assign the sketch line work as well.

IMAGE D

- And finally – my pet hate….

- Never, never, never use a Manufacturers name in the subcategory, line pattern or filled region naming. (I’ll discuss Shared Parameter naming for Manufacturer content another day too)

- Imposing a Manufacturers name into any project template settings is a very dominating and inconsiderate act. It is simply not appropriate and will only result in you alienating the end-user. There is absolutely no reason why ‘Mary’s coffee table’ can’t be included under the general ‘Table’ subcategory.

- No drafter will want to display Mary’s content in isolation. And…. if they ever did want to they could use a View filter (using the Manufacturer parameter value) to do this far more effectively with no negative impact on the project or template file environment.

- And finally using Manufacture specific subcategories only serves to communicate to all Design and Drafting firms that you (the content creation firm) do not understand how Revit family subcategories or Revit standards are intended to be used.

I could discuss even more things to do with subcategories but I think that’s more than enough for now. Hopefully this means that we can look forward to some new Manufacturer Revit ranges soon with much better subcategory settings and naming.

happy clients, happy life

You must be logged in to post a comment.